Kaizen: The Silent Power of Change

Some concepts that filter through time carry a wisdom that transcends eras. Kaizen is one such concept. At first glance, this Japanese word may seem simple, yet it encompasses a philosophy profound enough to touch every aspect of life. Meaning “change for the better,” Kaizen believes in the power of small, steady steps rather than large revolutions.

In the rapidly consumed success stories of the modern world, Kaizen suggests that we slow down, observe, understand, and aim to be a little better each day. It can find a place not only on the production lines of companies but also in our kitchens, the organization of our homes, and our personal habits. This is because Kaizen represents an approach to improvement that permeates life itself.

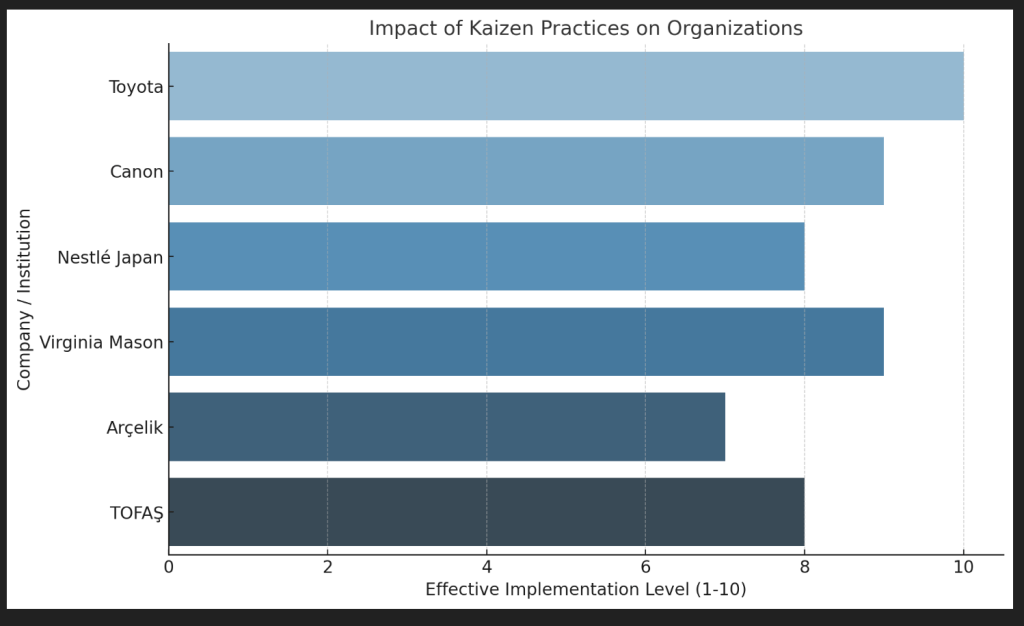

Global Examples of Kaizen Implementation

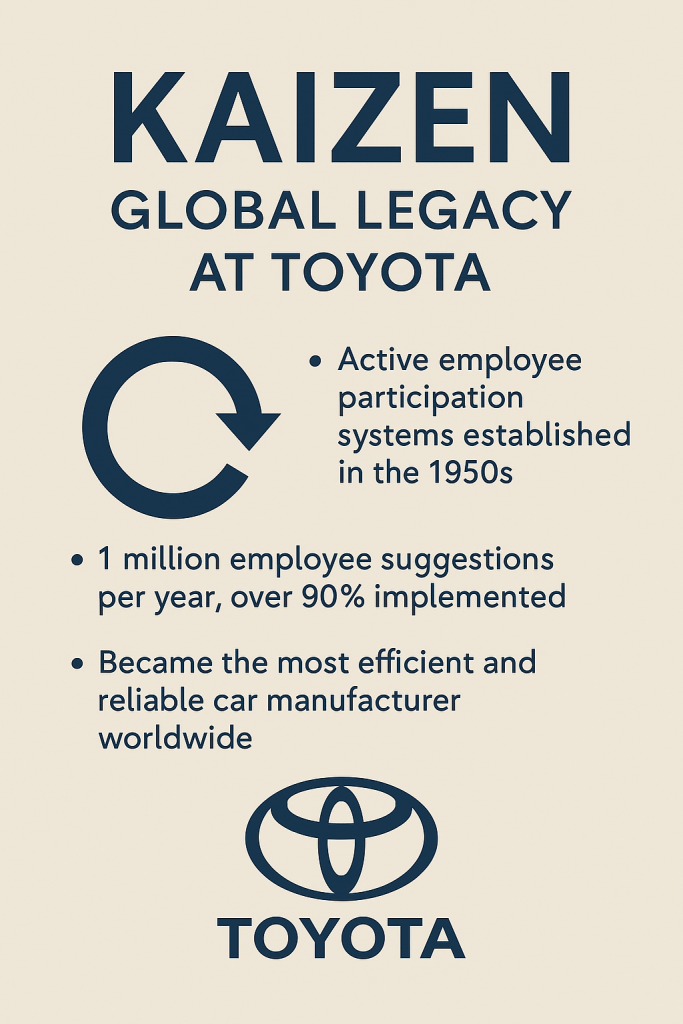

Toyota: The Global Kaizen Legacy

The gateway for Kaizen philosophy to the world was undoubtedly Toyota Motor Corporation. In the 1950s, despite limited resources, the company sought to increase its competitive power by establishing continuous improvement systems based on the active participation of employees. On average, they received 1 million employee suggestions each year, more than 90% of which were integrated into the production processes. The result? Toyota became not only Japan’s, but also the world’s most efficient and reliable automobile manufacturer. Today, this approach, known as the “Toyota Way,” is taught at Harvard Business School.

Canon: Small Steps in Pursuit of Perfection

In the 1980s, Canon, going through a challenging period, reinvented itself by embracing the Kaizen culture. The question “How can I do this better?” became a routine for every unit and employee. Even the smallest issues in processes were taken into account. This approach helped Canon become a global leader in printers and optical systems. Even in one of the most competitive sectors, its stable growth was driven by the discipline of Kaizen.

Nestlé Japan: Consumer-Centric Improvement

Nestlé Japan applied Kaizen not only in production but also in customer relations, achieving great success. With the philosophy that “customer complaints should be treated like gifts,” each complaint was viewed as an opportunity for process improvement. Customer loyalty reached record levels, and small packaging changes in Nescafé products visibly increased consumer satisfaction.

Virginia Mason Medical Center (USA): The Kaizen Revolution in Healthcare

This hospital in Seattle, USA, successfully adapted Kaizen philosophy to the healthcare sector. Micro-level, continuous improvements in patient safety, time management, and team coordination resulted in significant increases in both patient satisfaction and employee engagement. Additionally, the hospital saved millions of dollars in operating costs. The system has also served as a model for many other healthcare institutions.

Successful Practices from Turkey

In Turkey, industrial giants like Arçelik, TOFAŞ, Ford Otosan, Vestel, and Bosch Turkey have integrated Kaizen not only into their production processes but also into the entire corporate culture. At Arçelik’s Gebze plant, the “Kaizen Village” created by employee suggestions led to cost reductions, waste prevention, and quality improvement. In 2022, TOFAŞ was recognized in Europe as one of the automotive companies with the highest number of employee suggestions.

The Universal Teachings of Kaizen

One of the most impressive aspects of Kaizen is its view of mistakes not as threats, but as opportunities for development. This perspective can transform life whether it is in a production line, a school, or even in our own homes. For those who understand the power of small steps, Kaizen offers a calm but assured path to success.

Today, whether you are a CEO of a company or an individual trying to reshape your own life, Kaizen makes a quiet but profound call: “Better is possible.”

Tolga AKAGÜN

Yorum yazabilmek için oturum açmalısınız.